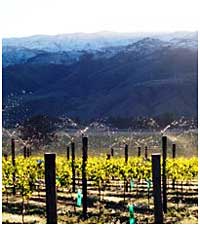

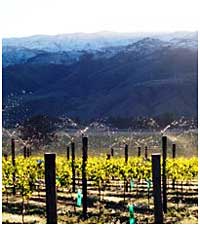

Flipper (along row) sprinklers used for targeted over head frost protection in a grape block

Using overhead sprinklers that spray water on plants is one of the most reliable methods of frost protection. The main features of the method are:

- low operational costs

- less polluting than alternative methods

- high installation cost

- large amount of water required.

In this factsheet, we outline how the method can be so effective and the design and operational features that will help you achieve robust frost protection.

How it works

Heat released into the orchard by irrigation water in frosty conditions can protect the crop from frost damage. Almost all of this heat comes from the latent heat of fusion, the heat released as the water changes from being a liquid to the frozen state. As it freezes, water applied at a rate of 1 mm/hr releases latent heat of about 100 W/m2, which is equivalent to about 10,000 domestic light bulbs running per hectare. A small amount of additional heat is released by the water as it cools, equivalent to about 1 W/m2 per degree of water temperature. Some of the applied water evaporates, absorbing heat as the latent heat of evaporation, reducing the total benefit of the applied water in mitigating frost damage. Evaporation losses can be significant when wind speeds exceed about 1.5 m/s; generally, wind speeds experienced on frosty nights are less than this.

Unlike protection techniques that involve mixing warm air present from inversion conditions (see factsheet HIP30), overhead irrigation works under both radiation and advective frost conditions and has successfully protected crops at temperatures as low as -6°C.

Water volume requirements

For effective frost control using overhead sprinkler irrigation, Growers must apply water at a rate:

- high enough to release sufficient latent heat that temperatures are prevented from dropping much below 0oC

- low enough to avoid unacceptable levels of waterlogging of the soil (see factsheet HIP24).

... a rule of thumb is that each millimetre of water applied per hour can maintain plant temperatures one degree above the frost temperature.

A useful rule of thumb is that each millimetre of water applied per hour can be expected to maintain plant temperatures one degree above the frost temperature. For example, an application rate of 4 mm/hr can hold plant temperatures at -0.5oC to 0oC in a -4oC frost. However, higher sprinkling rates will be required to ensure protection in situations where sprinkler cover on the crop is not uniform and/or in wind conditions where evaporative cooling becomes a factor. In such conditions, sprinkling rates of 1.5 mm/hr or more may be required to achieve a 1oC rise in plant temperature.

Ice encased leaves and flower following overhead sprinkler frost protection – note the clear ice which is indicative of near continuous wetting

The ice that forms on the crop as a result of overhead sprinkling is a good conductor of heat: it does not act as an insulating layer to prevent frost damage! Rather, it facilitates freezing of crop tissues unless a film of continuously freezing water is maintained on the surface of the ice, releasing sufficent latent heat to maintain temperature just below 0oC. You can easily check that this requirement is being met by looking at the ice being formed:

- when sprinkling rates have been acceptably high and freezing is continuous, the crop is covered in icicles of clear ice

- when sprinkling rates have been insufficient for continuous freezing, icicles tend to be absent and trapped air in the ice makes it white; tissue damage is likely to have occurred.

The total volumes of water required for sprinkler-based frost protection are far greater than those needed for irrigation. As the whole protected area needs to be wetted at the same time, the overall pumping capacities required far exceed those for systems used solely for irrigation. For a single typical spring frost event in New Zealand, full cover over-head sprinklers may need to deliver a total of 10-40mm of water (100-400 m3 of water per hectare). Typical weather patterns in New Zealand can produce a series of potentially damaging frosts over several days, so this amount of water needs to be available for several nights in succession. Planning for water storage and pumping capacity sufficient to provide protection under realistic worst case scenarios for frost risk is an important part of the design of sprinkler frost irrigation systems (see sprinkler options and operation plan notes below).

Water quality requirements

Water quality can affect the effectiveness of frost protection from overhead sprinklers. Generally, plant tissue within a layer of continuously freezing water will be maintained at temperatures between -0.5 and 0oC. However, water from bores or surface sources typically contains dissolved solutes that depress its freezing point to around -0.5oC. This means that the temperature of ice encased tissue will be below 0oC, but this is usually not a problem in terms of frost protection as the critical damage thresholds in most crops occur at temperatures below this.

It is essential that attention is given to water intakes and filtration where they are necessary. Failure to maintain a constant supply of water to the crop once temperatures drop below critical levels can further depress temperatures and cause more damage than if sprinkling had not been used at all.

Sprinkler options and sprinkler operation plans

Overhead circular pattern sprinkler used for frost protection on a Marlborough vineyard

Traditional systems for sprinkler protection of tree crops have used rotating impact sprinklers on top of 5m poles on 20m centres to provide full coverage of water at a rate sufficient for adequate protection in the hardest expected frost. The large jet size on this type of sprinkler minimises blockage problems.

In more recent times, developments in mini sprinklers, variable speed pumps and pulsed water control systems, allow water application rates and locations to be managed to provide reliable protection with significantly reduced use of water - potentially half that of full cover systems.

Some sprinkler systems, such as along-row flipper systems in grapes and overhead micro sprinkler systems in row tree crops, have been designed to just protect the target crop canopy. However, these systems are vulnerable to the water output being moved off-target in even light winds, with a risk of uneven and incomplete crop protection.

... sprinkler rotation rates should be around 30 seconds and never greater than 60 seconds.

The delivery pattern of rotating sprinklers or flippers means that continuous wetting of plant surfaces never occurs in practice. Likewise, partial obstruction of sprinkler output by support structures or plant limbs means that some areas of the crop canopy will receive lower and less consistent wetting than others. While the design of the sprinkler system to maximise evenness of coverage is best left to specialist designers, as a rule of thumb, sprinkler rotation rates should be around 30 seconds and never greater than 60 seconds. Note that the rotation rate of some sprinklers can be more than halved as ice forms on them.

Starting and stopping sprinklers

To minimise soil water logging and potential crop damage from overloading with ice, sprinkling times are usually limited to the minimum time that prevent frost damage. Be careful, though, to turn on sprinklers early enough to avoid problems caused by evaporative cooling that can depress tissue temperatures to a damaging level. This risk:

- occurs because air temperature in the sprinkled area falls towards wet bulb temperature – this can be significantly below the air temperature when starting humidity levels are low

- is subsequently reduced by warming of the orchard air as latent heat is released by the freezing of applied water on the ground and on plant surface

- can be avoided by turning on the sprinklers early, so that orchard temperatures have not dropped close to damaging levels and also to ensure that ice has not blocked lateral pipes and risers (exposed lateral pipes and risers can, like exposed buds and tissues, experience high radiant heat loss and can be 1-2oC lower than the surrounding air temperature).

Icicle formation following overhead vineyard frost protection using flippers

The decision when to start and stop sprinklers for frost protection should be based on both the temperature and humidity in the orchard. Sprinklers should be turned on or off when the wet-bulb thermometer temperature, measured upwind of the irrigated area, is above the crop’s critical damage temperature.

The wet bulb temperature (or ice bulb temperature when temperatures are below 0oC) is influenced by the amount of water vapour in the air, which is reflected in the dew point temperature. As a rule of thumb: The screen temperature (see factsheet HIP30) at which to start sprinklers should not be below 1oC when wet bulb or dew point temperatures are around -3oC and will need to be around 4oC when wet bulb or dew point temperatures are as low as -9oC.

When turning off sprinklers, melting ice draws heat from the crop and surrounding air. Provided the wet bulb thermometer temperature is above the crop damage threshold temperature, this cooling effect will not damage the crop. Note that wet bulb temperatures can still be below zero even when the sun is up and air temperatures have risen above 0oC.

Testing the system

Any new overhead sprinkler system should be tested during winter, while the crop is still dormant and less susceptible to frost damage. This provides a good opportunity to learn to manage 'turn on' and 'turn off' procedures and to confirm that the system can provide the level of crop wetting required to ensure protection.

Next steps

With an over-canopy irrigation system as a primary line of active defence against frosts, you may want to enhance your ability to engage it most effectively by:

- understanding the influence of factors affecting the amount of water vapour in the air (see factsheet HIP48)

- considering factors that increase the probability of radiation and advective frosts (see factsheet HIP30)

- recognising stages of crop growth when susceptibility to frost is greater (see factsheet HIP41)

- implementing technologies for monitoring and forecasting frost risk (see factsheet HIP14).

Summary

Positive points of overhead sprinklers for frost protection:

- Overhead sprinkling can successfully protect crops through significant (-6oC or lower) freezing events provided sufficient water is available to provide a continuous wetted film on the surface to be protected.

- Overhead sprinklers are the only large scale outdoor frost protection method that can be expected to work under both radiation and advective frost conditions.

- Sprinklers are quiet and water pumping costs are significantly lower than the running costs of heaters, helicopters or wind machines.

Negative points of overhead sprinklers for frost protection:

- The water volumes required for effective frost protection are very large and will require legal water use consents, a water storage system (probably) and significant expenditure on pumping and sprinkler systems in addition to that for irrigation requirements.

- Should the tissues freeze, frost damage will be more severe than when water is not used at all

- Potential soil structure damage, water logging, leaching and erosion issues arising from application of large volumes of water.

- Potential increase in plant root and foliar disease problems.

- Potential plant and support structure breakage as a result of ice loads during frost protection.

References Evans, R.G. 1999. Frost protection in Orchards and Vineyards. USDA-Agricultural Research Service. 20pp.

John. P.H. 1985. Overhead targeted frost protection. New Zealand Agriculture Engineering Institute Project Report 33. 74pp.

Ireland W. 2005. Frost and Crops: Frost prediction and plant protection. ISBN 0-473-10108-4 165pp.

Snyder, R.L.; J. Paulo de Melo-Abreu. 2005. Frost Protection: fundamentals, practice, and economics. Volume 1. Food and Agriculture Organization of the United Nations, Rome, 2005. http://www.fao.org/docrep/008/y7223e/y7223e00.htm

Woodhead, I.; Richards, S.; Hayward, A. 2007 Improving Sprinkler Frost Protection In New Zealand Vineyards: Summary Report from 2004-7 Data. Report No LTE02129/2, Version 1.01 Lincoln Ventures Ltd. 69pp.

This factsheet may be cited as:

Staff Writer. Overhead sprinkler irrigation for active frost protection. NZ Avocado Industry 26 Aug 2009. (accessed 4 Feb 2026) <http://www.hortinfo.co.nz/factsheets/fs79-45.asp>.

The NZ Fruit Industries Collective and/or its partners (NZFC) have endeavoured to exercise reasonable skill in obtaining and presenting the information in this document and its attachments, however NZFC make no warranties, representations about or guarantees the information in this document or its attachments in any way and no party making any use of the information or relying on it in any way shall have any claim against NZFC for any loss suffered in any way as a result thereof. The material in this document and its attachments is intended for information purposes only and is not a source of legal advice.

Consumer

Consumer